About A Verre

Origin

The name "A Verre," translating from French as "A Glass" or "A Bottle," is not just a name. It's a tribute to our founder's rich French-Caribbean lineage.

This heritage is more than just a backdrop; it's the heart and soul of the brand, shaping the philosophy and approach, and reimagining a holistic experience centered around flavor and innovation.

Ingredients

Since the inception of A Verre, it has always been a part of the philosophy to get maximum aromatic output from small biomass. In order for this to succeed, our ingredients need to be of the highest quality.

We have one very clear goal in terms of ingredients; we want to buy straight from the farmers, or from exporters that buy directly, thus never having a value chain longer than 2 links. This enables us to cooperate with farmers prioritizing flavour over volume. We are always thrilled to receive ingredient samples expanding our network of farmers, paying a premium for quality.

Fermentation

Fermentation is something we take a lot of pride in. While it is a convenient possibility to buy a base spirit and re-distil it with botanical, we have chosen to create it from scratch. The results we achieve in terms of flavour by going through the cumbersome motions of fermentation are undoubtedly worth it. We work with a variety of yeast strains & substrates which allow us to take turns down unexplored paths.

We love to push the boundaries of materials and technology in our production. One of the great lessons we learned from our travels in the Caribbean is the abundance of plastic fermentors. Now plastic gets a bad name, and in many cases deserved, but plastic is a true marble of technology of the 20th century. When used and re-used correctly it can be nothing short of amazing.

We use High-Density Polyethylene egg-shaped fermentation tanks. The material’s molecular composition, allows the ferment to breathe, hence oxygen can slowly pass through the tank and into the ferment. In addition, the material is an insulator of heat, while the egg-like shape facilitates a circular flow of convection that generates heat. Both allow us to save energy.

Destillation

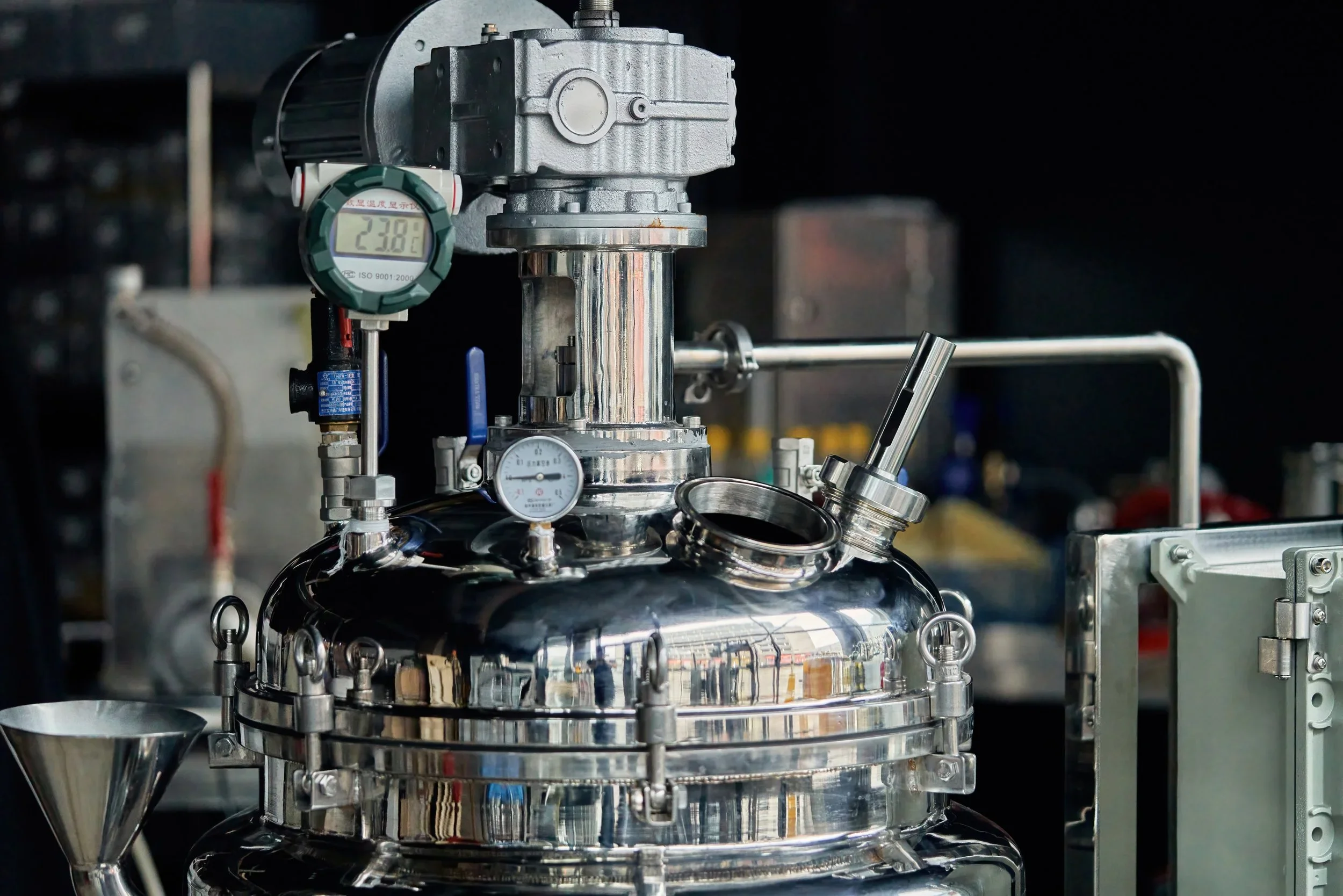

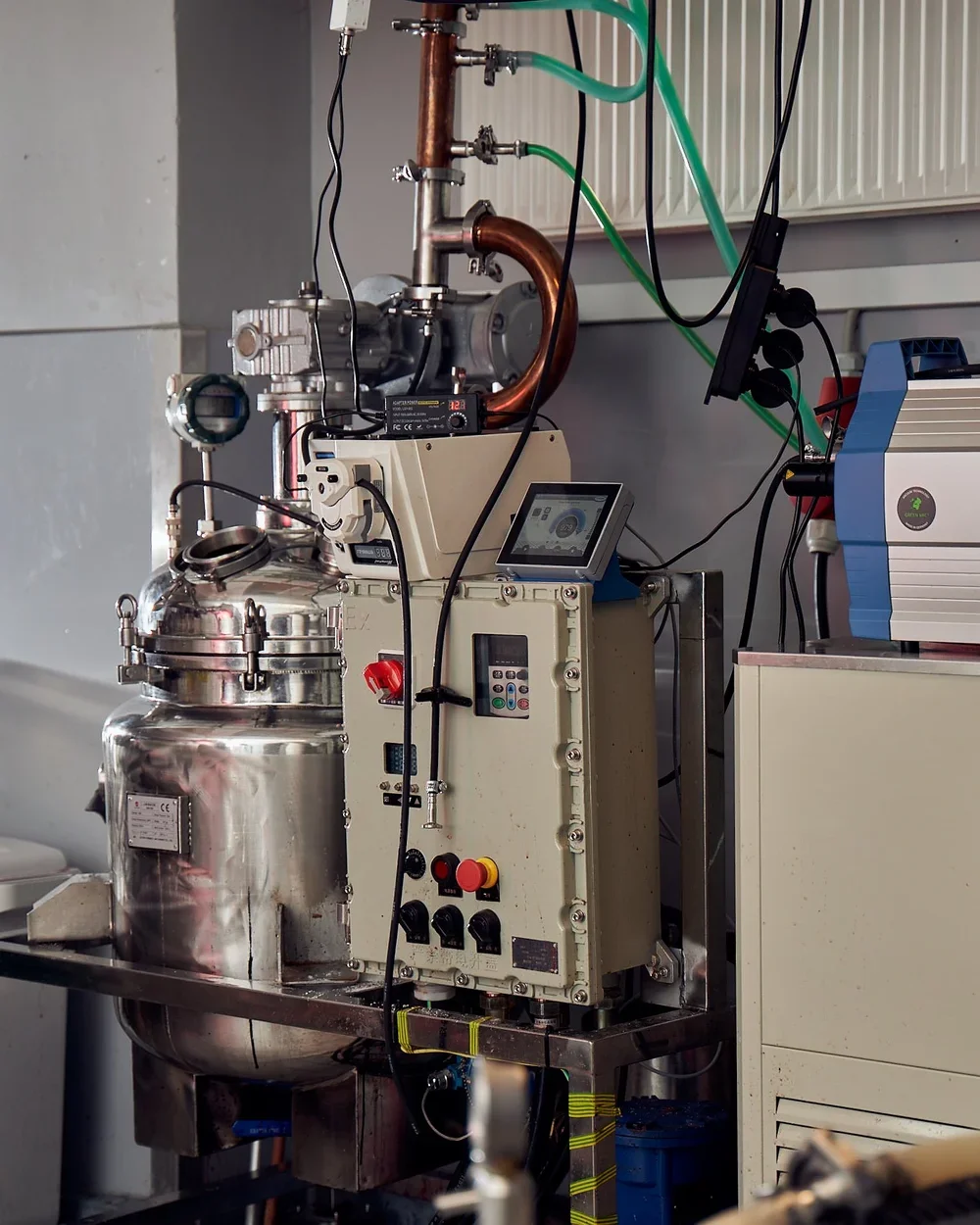

We take inspiration from the Rotary-Evaporator, or in shorthand Rotovap, however, designed for a more limited purpose, but featuring new technology in both extraction rates, and distillation speeds, not to mention energy efficiency

While the Rotavap manufacturer commercial first by Buchi in 1957, remains a favourite for prototyping due to its multifaceted and versatile nature, in-sourcing the fermentation of base spirit significantly increased the scale requirements in distillation. Inspired by the rotavap and our advances within alcohol free extraction technology, we have designed the dual-function reactor for both extraction and distillation.

Extration

Extraction in this case is the transferral of flavour molecules from our ingredients to our medium, either water, sugar and/or alcohol. We use our reactors to control the pressure, temperature, duration and kinetic, sonic and thermal energy used to mix ingredients and mediums. This process is used for all products.

Generally, you need at least one of two elements for extraction: energy or time. Time is not an ideal quantity for producing products as it makes production planning harder and essentially makes the product more difficult to control and more expensive when hitting the shelves.

Energy requires experience and understanding of its use but it will ultimately reduce time needed for extracting and more essential to us, it allows many of our ingredients to unfold their true flavour potential as many fragile and delicate notes only become detectable when produced under some kind of energy manipulation.

To that end our Head Distiller designed and built our bio reactors. It allows us to alter a myriad of conditions in such a way each product gets the optimal conditions, making sure that we are in control of the development of the extraction and eliminating the unwanted flavour components found in every ingredient. We can control the air pressure within the reactor, temperature, and many other kinetic forces and this reduces our extraction time significantly, while extracting the maximum amount of desired flavour.